Each Squink/SV2 inkjet cartridge requires some simple maintenance in order to operate at peak efficiency. We want to share a couple of tips that we know will guarantee fewer clogged nozzles and the finest quality traces and definition.

Here's a little cheat sheet that covers the basic rules.

| Type | Storage Temperature | Storage Conditions | Cleaning Solution |

| Insulating Ink (Blue) |

Room Temp. 20-25 °C 68-77 °F |

- Keep in the protective clip when not in use - Keep in a cool and dark place |

Isopropyl Alcohol, 90% or higher concentration |

| Conductive Advanced Ink (Red) |

Room Temp. 20-25 °C 68-77 °F |

- Keep in the protective clip when not in use - Keep in a cool and dark place |

Deionized Water |

Follow these rules and your cartridge should be safe for at least 6 months or longer. Following the tips below will help a lot as well. Read on!

Tips for a Perfect Print

Shaking With the Clip On

Shake the cartridge with the protective clip on for about 20 seconds. This helps bring moisture to the nozzles and break air dams that may have been created on the nozzles.

Shaking With the Clip Off

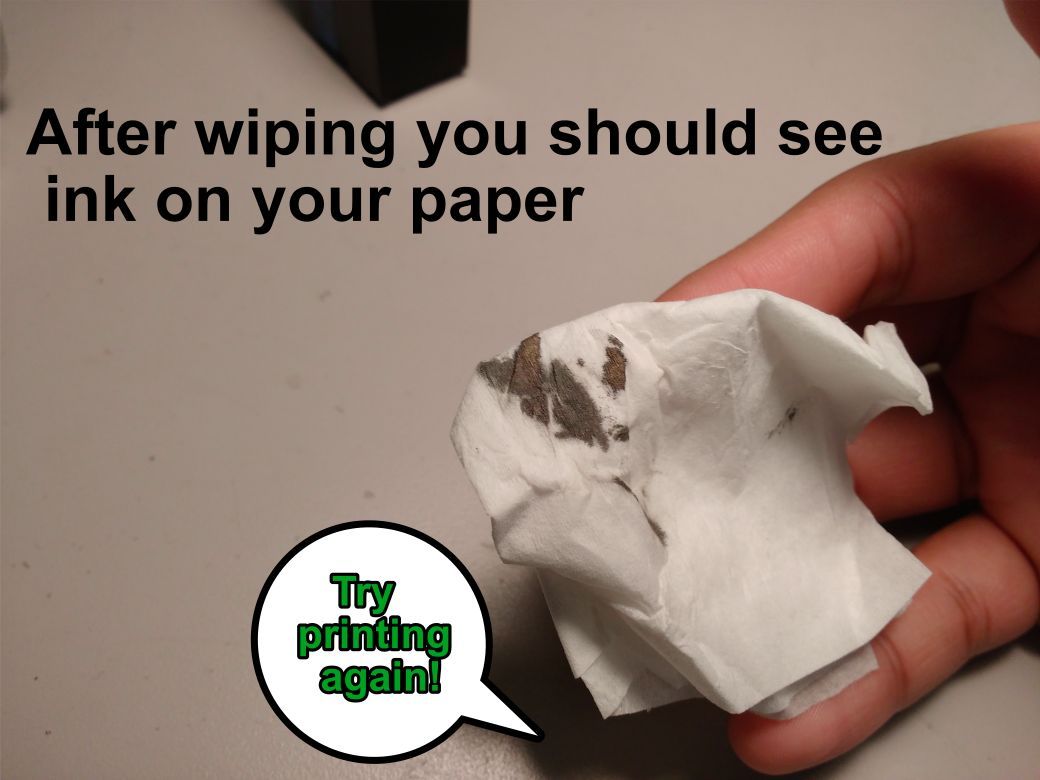

If when you start printing you see nothing coming out of the nozzle, try shaking the cartridge with the clip off, and placing a wipe on the nozzles. This wipe is to be held in place while shaking. Do you see ink on the wipe? For SV2, you should see two parallel lines, about 1/2 inch long.

If you try shaking several times with the wipe on the nozzles, and you still see no ink, maybe you run out of ink, or the nozzles are clogged.

Proper Wiping for nozzle unclogging.

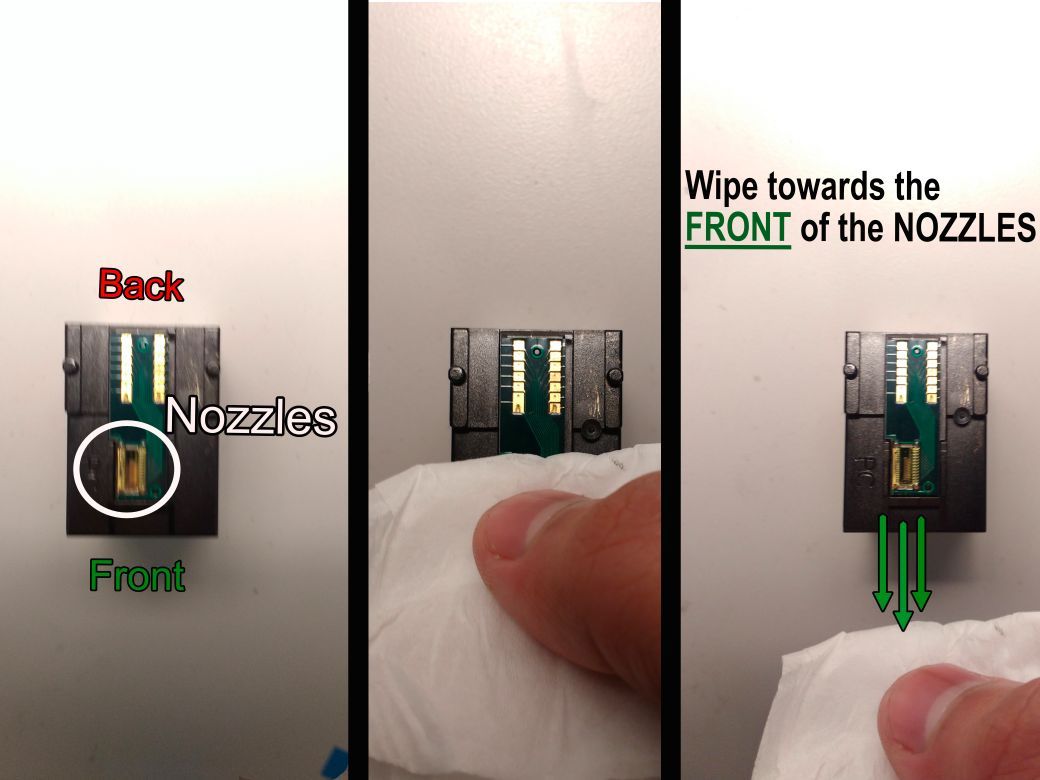

If wiping is required, follow these basic rules of thumb:

- The wipes used should not leave residues of fibers behind. Use NO-LINT wipes.

- Use the cleaning solution recommended for your ink.

- Wipe in a single direction: AWAY FROM THE CONTACTS. This reduces the chances of scratching.

- Wipe away from the cartridge connectors. This avoids contaminating the connectors with the ink.

Still Can't Print?

If you still are unable to print anything with your Squink PCB Printer after trying all of these tricks, email BotFactory's support team at support@botfactory.co.