BOM Optimization to Ensure Time-to-Market and On-Time Delivery

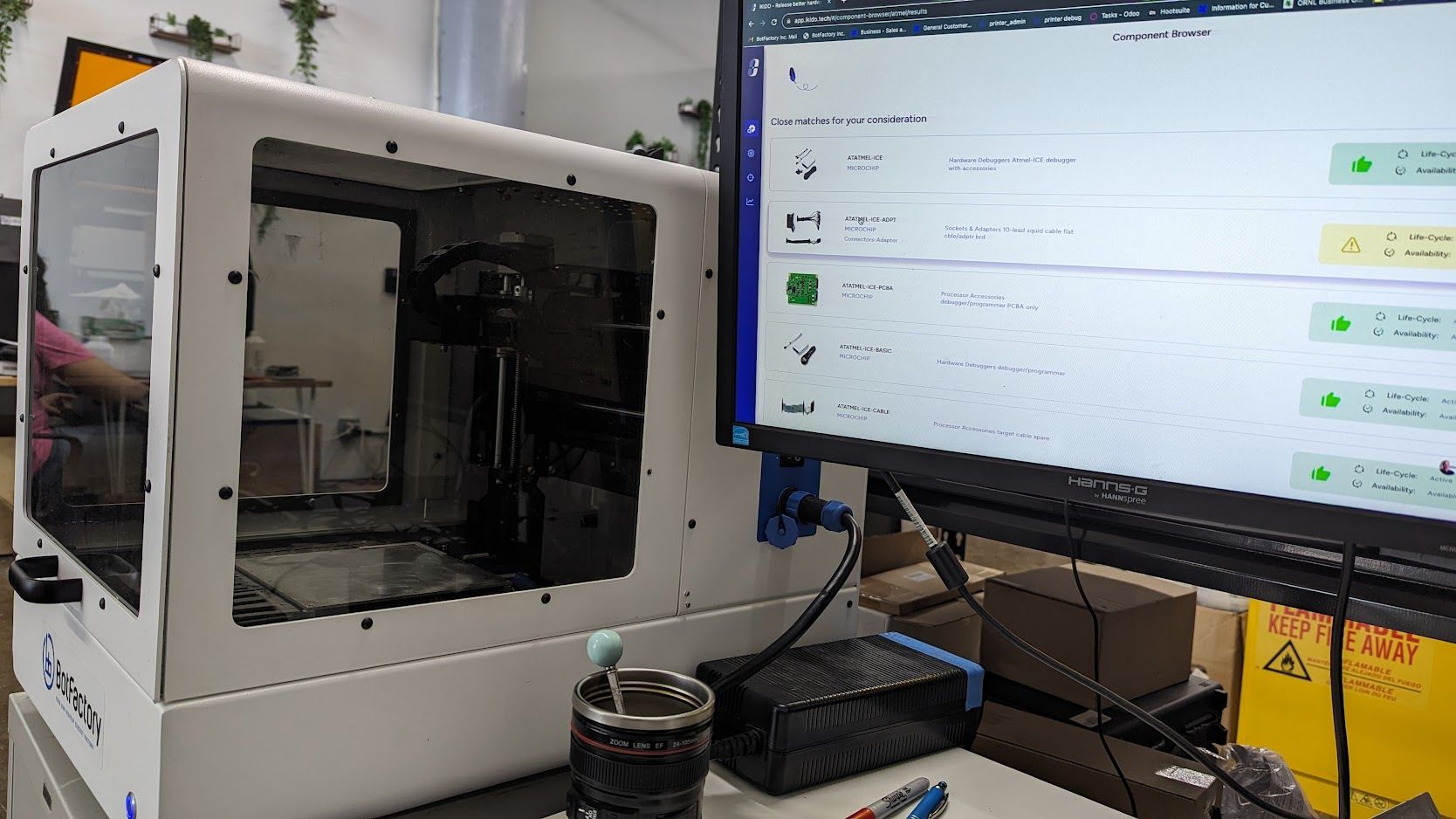

In product manufacturing, the bill of materials (BOM) is king. It impacts a product's time-to-market (TTM) and on-time delivery (OTD). A fully optimized BOM ensures that the correct components are sourced at the right time to meet production schedules. For example, PCBs created from our BotFactory SV2 Printer benefit from an optimized BOM, ensuring rapid prototyping and high-quality 3D printed PCB production.

The global market demands quicker turnarounds and higher-quality products; that's how to stay ahead. Businesses need to focus on BOM optimization, which can give them an edge over the competition. The right BOM, when managed effectively, can prevent costly production errors, reduce waste, increase resilience, and streamline the manufacturing process.

The SV2 PCBA Printer's rapid prototyping capabilities and material versatility directly influence the time-to-market of any 3D printed electronic circuit product... but you will need to have the components at hand to take advantage of this revolutionary technology.

Integrate digital tools for BOM management

Manual BOM management can be time-consuming and error-prone. Businesses can automatically update, validate, and maintain their BOMs by leveraging advanced digital solutions. Platforms like the IKIDO BOM optimization platform provide valuable resources and tools tailored to enhance BOM management. They offer integrated solutions that cater to the specific needs of businesses, ensuring that their production remains agile, efficient, and timely.

Incorporating such tools helps reduce errors and provides insights through analytics, assisting businesses to make informed decisions, forecast potential challenges, cut costs, and continually refine their processes to ensure they meet TTM and OTD.

Key benefits of BOM optimization

BOM optimization can drive businesses forward and give the edge to ensure a proper TTM on OTD. Here are some key benefits when optimizing BOM:

- Efficient resource allocation: An optimized BOM ensures that every resource, raw materials or labor, is used most efficiently, which means fewer delays due to material shortages or miscommunications.

- Reduced production errors: A detailed and precise BOM leaves little room for error. It specifies each material's quantity, quality, and source, reducing the chance of using incorrect or substandard components. This is especially crucial when using a PCB printer machine like the BotFactory SV2 for complex 3D printed circuit designs.

- Cost savings: By streamlining the procurement and production processes, businesses can benefit from bulk purchasing, reduced waste, and decreased downtime, all of which contribute to significant cost savings.

- Enhanced collaboration: A well-maintained BOM facilitates better communication between departments. When everyone from design to procurement to production is on the same page, it significantly reduces the chances of delays.

- Supply chain transparency: An optimized BOM provides clear visibility into the required materials and their sources. Transparency ensures that every stakeholder understands their role and requirements, from suppliers to manufacturers, thereby streamlining the supply chain process.

- Scalability: With an optimized BOM, businesses can more easily scale their production up or down based on market demand. This allows flexibility that can be especially beneficial in industries with seasonal needs or rapid product life cycles. Plus, creating PCBs on a mass scale is much easier when choosing the correct BOM.

- Improved quality control: A comprehensive BOM sets specific standards for every component, assisting quality control teams in ensuring that every product meets or exceeds these standards, leading to consistent product quality and fewer defects.

- Forecasting accuracy and shortage avoidance: A detailed BOM allows businesses to predict future material needs and shortages more accurately. It leads to better inventory management, reducing holding costs, and minimizing the risks associated with stock outs or overstock situations. For instance, companies will know beforehand to avoid NRFND components when scaling, etc.

- Facilitated compliance and certification: An optimized BOM can outline required compliant materials or processes for industries that must adhere to specific regulations or achieve certain certifications, making it easier for businesses to meet industry standards or regulatory requirements.

- Enhanced product lifecycle management: With a well-managed BOM, industries can more effectively track changes and updates throughout a product's lifecycle, from initial design to EOL. Leading to more efficient product updates and on-the-fly iterations.

- Reduction in lead times: An accurate BOM can expedite procurement, ensuring that necessary materials are ordered and received promptly. It reduces lead times, allowing products to reach the market faster.

Are there other ways to optimize your BOM?

There are several strategies that companies can employ to optimize their BOM, from methodology, choosing the right supplier, improving forecasts, and planning to BOM optimization platforms; we will cover some of them:

Simplify the BOM

A complex BOM with too many line items will be difficult to manage. Companies should simplify their BOM as much as possible by reducing the number of unique parts and standardizing components. Standard functions can be consolidated into a single line item. Features with long lead times or availability constraints should be flagged. A clean, streamlined BOM gives procurement and production teams clearer visibility, makes the BOM easier to maintain, and contributes to faster TTMs.

Select optimal suppliers

Choosing suitable suppliers for each component is critical to optimizing the BOM for on-time delivery. Criteria for selecting suppliers include lead time, availability, quality, and, of course, cost. Dual-sourcing high-risk features can help mitigate supply chain disruptions and improve OTD. Building strategic partnerships with key suppliers gives a company greater assurance of getting the parts they need when needed.

Improve forecasting

Inaccurate demand forecasting can lead to parts shortages or excesses. Improving forecasting accuracy for individual components allows for better BOM planning. Forecasting should consider factors like seasonality, production changes, and market trends. Advanced analytics, AI tools, and BOM management software can help identify patterns and improve forecasting precision.

Conclusion

In an era where efficiency and precision are desirable and essential, BOM optimization emerges as critical for successful product manufacturing and delivery. Its wide-ranging benefits, from supply chain transparency to improved quality control, highlight its pivotal role in meeting the market's demands.

For businesses aiming to stay ahead of the curve, investing time and resources into refining their BOM processes is not just a best practice, it's a strategic imperative. By doing so, they can ensure that their products not only resonate in terms of quality and reliability but also reach their intended markets in a timely and cost-effective manner.

Companies can significantly enhance their time-to-market and guarantee on-time delivery by ensuring that the BOM is meticulously managed and optimized, especially when utilizing advanced PCB 3D printers like BotFactory's SV2.

IKIDO's platform displays available components for use with the SV2.