Steel to Skin: Revolutionary Applications of Printed Electronics in IoT and Wearables

In the rapidly evolving field of printed electronics, two recent groundbreaking studies highlight significant advancements that promise to reshape both the Internet of Things (IoT) and wearable technologies.

A Circular Economy with Printed Circuits on Steel

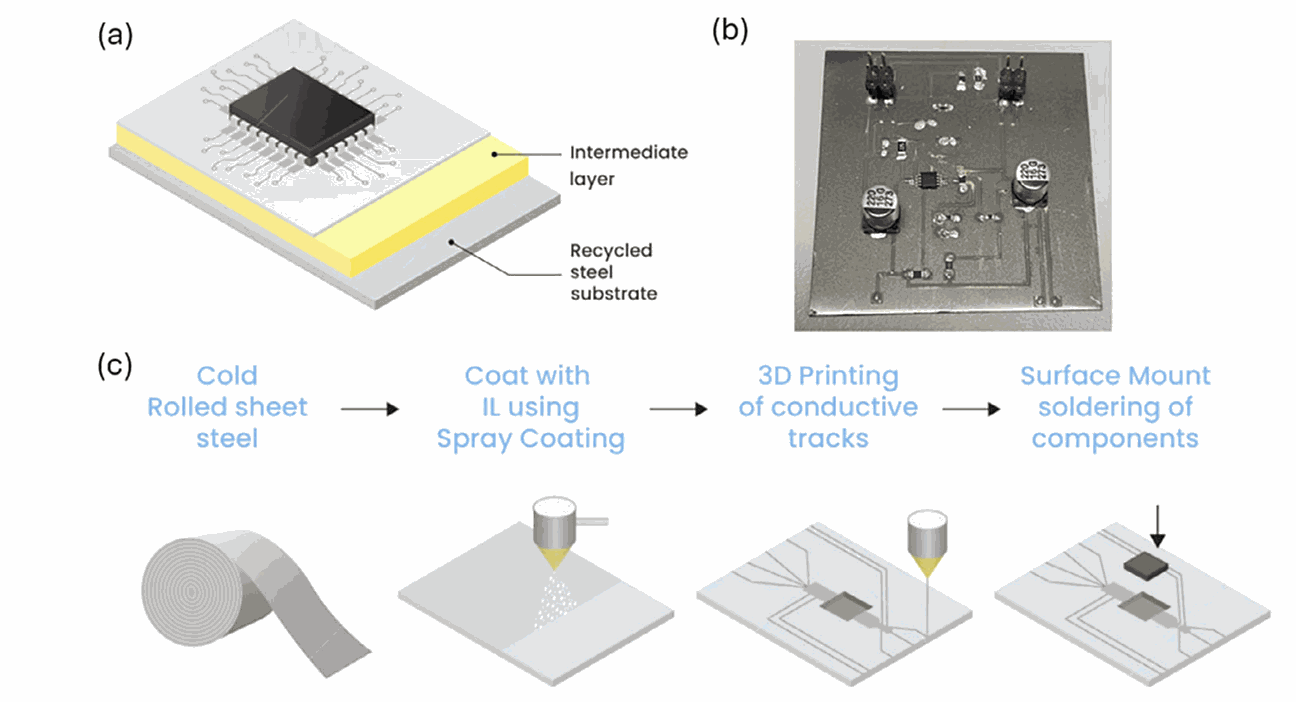

Researchers from the University of Glasgow and Idonial have developed an innovative approach to electronic circuits, presenting 3D printed circuit(s) on reusable steel substrates. This technology not only enhances sustainability but significantly reduces electronic waste, supporting a robust circular economy in electronics manufacturing. Unlike traditional printed circuit boards (PCBs) using fiberglass (FR-4), this new technology employs steel substrates coated with low-cost, insulating sol-gel layers. Conductive tracks and solder pads are then printed directly onto these surfaces, creating robust, reusable circuits suitable for wireless applications such as RF components and Wi-Fi nodes. Crucially, these printed circuits feature recyclable 3D scaffolds that can support high-performance, broadband IoT applications up to 6 GHz. At the end of their lifecycle, these steel-based PCBs can be easily recycled using non-hazardous solvents, enabling rapid recovery of valuable metals and components, significantly cutting down on environmental impact and aligning with international e-waste directives.

The University of Glasgow team leveraged the BotFactory SV2 printer to prototype and optimize conductive layouts directly on steel substrates. The SV2’s precise inkjet printing enabled rapid iteration of complex circuit patterns with high resolution, bypassing traditional fabrication delays and costs. As noted in their paper, “The use of desktop inkjet printing via the SV2 platform allowed for rapid optimization of conductive traces on steel, ensuring reliable electrical performance while maintaining mechanical flexibility.” This integration of desktop additive manufacturing accelerated R&D cycles and proved critical to developing recyclable circuits capable of supporting broadband IoT up to 6 GHz.

This approach represents a notable shift in how we think about PCB materials. Steel, traditionally considered too heavy and inflexible for electronics, becomes a viable substrate when paired with smart coatings and printed conductive layers. The recyclable nature of the sol-gel insulating layer means manufacturers can reclaim expensive metals like silver and copper with minimal environmental cost. By leveraging additive manufacturing for the conductive tracks, the process reduces waste and enables rapid iteration—key for IoT devices which often require bespoke or small-batch production. This is especially relevant as IoT expands into industrial, environmental, and consumer sectors demanding sustainable solutions.

Figure: Shows the schematic of the PCB manufactured onto steel substrates, including photographic images of the finished PCB and process flow for converting steel into functional PCBs.

Wearable Technology Enhanced by 3D-Printed Microfluidics

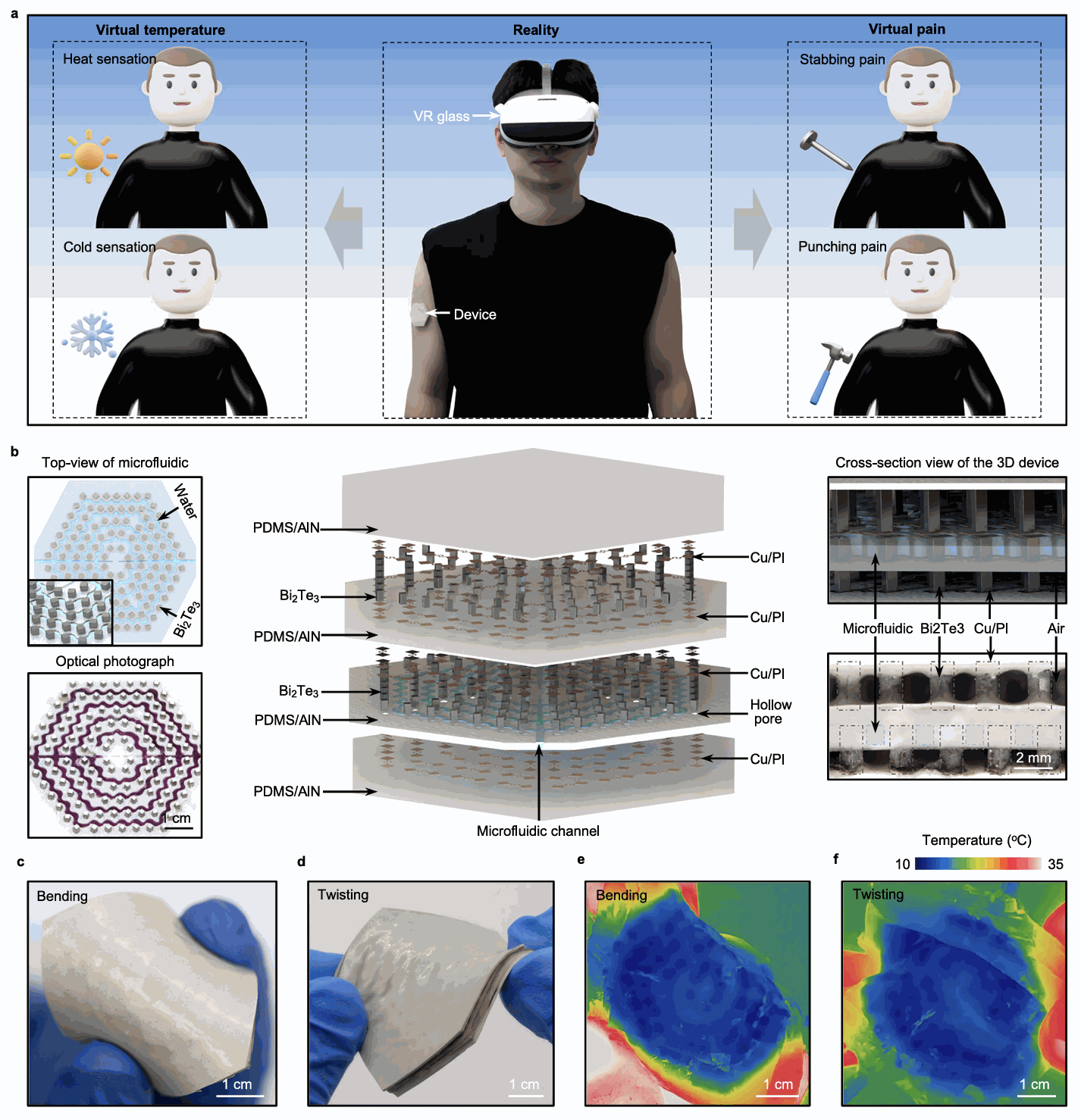

Another revolutionary application comes from researchers at the University of Electronic Science and Technology of China, who introduced a groundbreaking wearable system featuring microfluidic-enabled, three-dimensional, stretchable thermoelectric devices.

Conventional wearable devices often suffer from poor heat dissipation, severely limiting their power and usability. Addressing this, the team used 3D printing combined with laser etching and specialized elastomeric materials to create wearable thermoelectric devices with integrated microfluidic cooling systems. This approach significantly boosts heat exchange, enabling stable temperature control even under high-power operation, making it ideal for advanced wearable applications.

This microfluidic integration allows for precise temperature regulation, capable of achieving a substantial 11°C reduction on skin temperature, which paves the way for advanced virtual temperature and pain sensation applications. Users can experience finely controlled cooling and heating sensations, opening new possibilities in virtual reality and interactive technologies. The integration of microfluidics into stretchable thermoelectric devices addresses one of the biggest challenges in wearables: maintaining performance without overheating. Unlike conventional rigid thermoelectric modules, this technology offers mechanical flexibility and enhanced thermal management through fluid circulation, improving comfort and safety.

Moreover, the ability to dynamically control skin temperature enables new modalities for human-machine interaction and medical therapies. For instance, controlled cooling could assist in pain relief or inflammation reduction, while heating elements might simulate environmental feedback in immersive virtual reality experiences.

Figure: Shows the microfluidic-integrated, stretchable thermoelectric device design, detailing how microfluidics significantly enhance heat dissipation and temperature management.

Implications for Future Electronics

Both studies underscore a significant shift towards more sustainable, efficient, and multifunctional printed electronic devices. By bridging the gap between advanced materials science, printing technology, and sophisticated thermal management, these innovations highlight how printed electronics are set to transform consumer electronics, healthcare, and industrial IoT.

In essence, from durable steel-based PCBs supporting circular economies to sophisticated wearable devices capable of precise thermal management, the future of electronics is being redefined by printed technologies.

References

- Kettle, J. et al. (2025). Toward an Internet of Things Circular Economy Using Printed Circuits on Reusable Steel Substrates. Advanced Electronic Materials. https://doi.org/10.1002/aelm.202401234

- Zhang, Y. et al. (2025). Microfluidic-enabled three-dimensional stretchable thermoelectrics. npj Flexible Electronics. https://doi.org/10.1038/s41528-025-00234-7