In the dynamic world of technology, the Internet of Things (IoT) and the Industrial Internet of Things (IIoT) have emerged as transformative forces. These technologies are turning everyday devices and industrial systems into interconnected, smart solutions that enhance efficiency and productivity. The increasing demand for IoT and IIoT devices calls for rapid, flexible, and cost-effective development methods. 3D PCB printing is at the forefront of this revolution, reshaping electronics prototyping and manufacturing, with BotFactory's advanced SV2 Printer leading the way.

The Evolution of Electronics Prototyping

The Beginnings

Traditional PCB fabrication, while foundational to electronics manufacturing, encountered significant hurdles such as lengthy lead times, high costs, and a lack of flexibility, all of which frequently stifled innovation. The emergence of 3D printing technology across various industries heralded a new era of design and manufacturing flexibility. This technological leap extended to the realm of electronics, enabling the production of 3D printed PCBs and opening new avenues for prototyping and production.

A Leap into Electronics

As 3D printing technology matured, it catalyzed a transformative shift in the electronics sector. The introduction of PCB 3D printers marked a revolutionary step in prototype development. BotFactory's SV2 Printer stands as a beacon of this innovation, facilitating the rapid prototyping of 3D printed circuit boards with an unmatched level of speed and precision.

IoT Devices and the Smart Revolution

The IoT Boom

The seamless integration of IoT devices into our daily lives has marked the beginning of a new era of smart living. The exponential growth of IoT applications has highlighted the critical need for swift prototyping and iteration processes, areas where traditional PCB manufacturing techniques have proven inadequate.

The Role of 3D PCB Printing in IoT Development

In the dynamic world of IoT development, 3D PCB printers, particularly BotFactory's SV2 Printer, have become indispensable. These state-of-the-art machines facilitate the on-demand fabrication of 3D printed electronic circuits, drastically enhancing the design process and shortening the time to market for innovative IoT solutions.

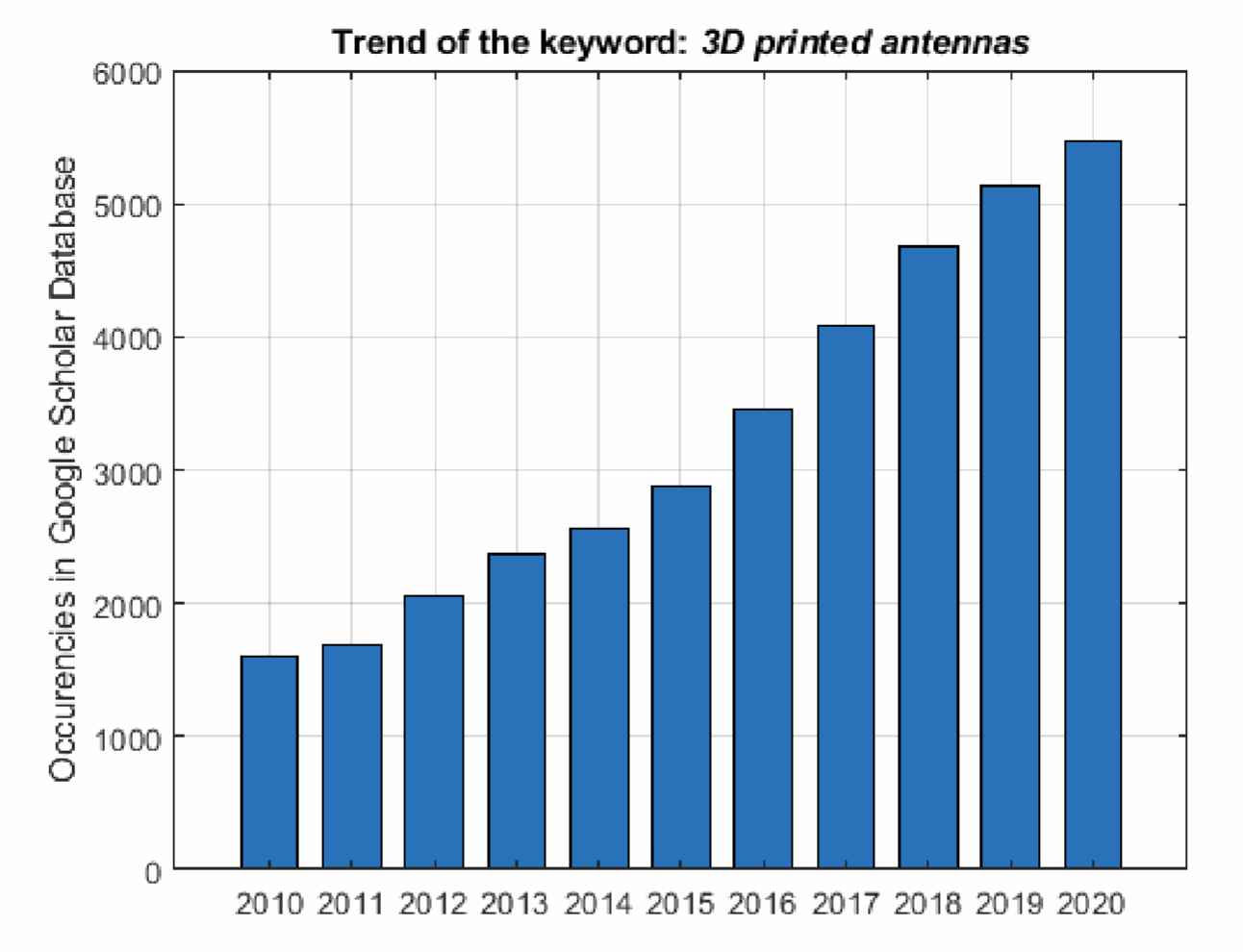

Trend of the keyword: 3D printed antennas

The graph in Figure 1 illustrates the growing interest and research in 3D printed antennas over the past decade, as indexed by Google Scholar. This surge reflects the expanding role of 3D printing in electronics, particularly in the development of components for IoT devices. The peak in 2019 suggests a heightened focus on this technology, likely due to its ability to produce antennas with complex geometries, which are both compact and efficient.

The integration of 3D printed antennas in IoT devices is a testament to the technology's potential. As shown in the paper "Dielectric Resonators Antennas Potential Unleashed by 3D Printing Technology: A Practical Application in the IoT Framework," 3D printing is not just revolutionizing PCB prototyping but is also enabling the creation of advanced components like wideband dielectric resonator antennas. These components are optimized for IoT devices, highlighting the significant benefits of 3D printing in developing compact, efficient, and high-performance solutions for the IoT era.

Figure 1: Trend of the term "3D printed antennas" in the Google Scholar database over the last ten years.

Case Studies and Examples

Creating a Smart Outlet

The project of creating a smart outlet exemplifies the SV2 Printer's capacity for rapid iteration of complex designs, facilitating the realization of innovative smart home technologies.

Designing and Building a UV Sanitizer

In response to global health concerns, the SV2 Printer was utilized to design and build a UV sanitizer, demonstrating the printer’s critical role in fast-tracking the development of health and safety devices. This case study exemplifies how 3D printed PCB technology can be applied to create timely solutions for public health.

Conclusion

The intersection of IoT device development and 3D PCB printing, led by pioneers like BotFactory and their SV2 Printer, marks a pivotal moment in the technological landscape. This synergy not only accelerates the pace of innovation but also democratizes the process of electronics design. As we move forward, the role of 3D printed PCBs in driving IoT advancements will only grow, promising an exciting future for smart device development.

A Call to Action.

Explore the potential of 3D PCB printing for your IoT projects with BotFactory’s SV2 Printer. Dive into the world of rapid prototyping and bring your innovative ideas to life faster and more efficiently than ever before. Visit BotFactory's website to discover how the SV2 PCB printing machine can revolutionize your development process, opening new avenues for creativity and innovation in the IoT space.

References

1. Chietera, F. P., Colella, R., & Catarinucci, L. (2021). Dielectric Resonators Antennas Potential Unleashed by 3D Printing Technology: A Practical Application in the IoT Framework. Electronics.