SV2 - Technical Specifications

Printing

Inkjet Conductive & Insulating Inks

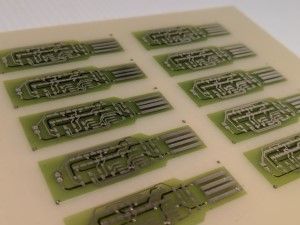

SV2 inkjet prints low-resistivity conductive inks and dielectric insulating inks to make Printed Circuit Boards (PCBs) in minutes on a variety of stiff and flexible substrates.

SV2 sequentially prints conductive traces and insulating layers, building vias in the dielectric layer to interconnect layers.

Specifications

| Print Technology | Thermal Inkjet Printing |

| Number of Inkjet Nozzles | 300 |

| Ink Types (curing method) | Conductive (heat), Insulating (UV) |

| Min. Trace Width | 8 mils [200 microns] |

| Min. Pin Pitch | SV2 – Starter: 24 mil [600 microns] SV2 – Enhanced: 20 mil [500 microns] SV2 – Professional: 16 mil [400 microns] |

| Min. Via Dimension | Diameter: 25 mil [600 microns] Drill Size: 15 mil [400 microns] |

| Max. Printable Area | 4.6" x 5.5" [117 x 140 mm] [X/Y] |

| Conductive Ink Sheet Resistance | 40 mOhms/square |

| Number of Layers | 1-2 (Starter), 1-4 (Enhanced) or 1-6 (Professional) |

| Part attachment | We recommend using our strong conductive epoxy. Soldering using the copper PCB rivet tool (sold seperately) |

| Supported Formats | GERBER RS-274X, . jpg, .png, .tiff, .bmp |

Dispensing

Extrude Conductive Glue or Solder Paste

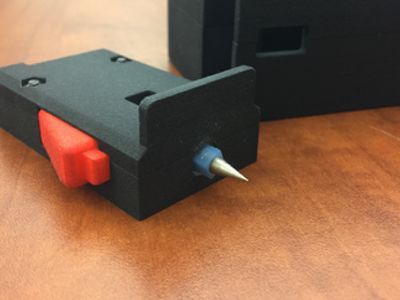

Lay down conductive glue or solder paste on printed or pre-fab boards in minutes using the Paste head.

SV2 takes eyesight and shaky hands out of the equation by precisely depositing on every pad.

Specifications

| Paste Technology | Syringe Extrusion |

| Paste Types | Conductive Epoxy and Solder Paste |

| Extruded Dot Size | 8 mils [200 microns] |

| Curing Method | Heat |

| Supported Formats | GERBER RS-274X, . jpg, .png, .tiff, .bmp |

PCB Assembly

Pick and Place Components

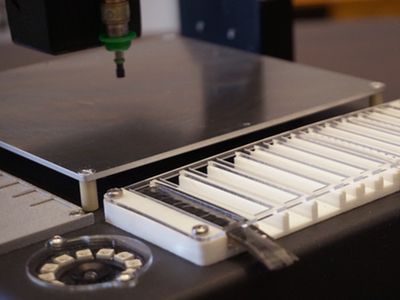

SV2 picks and places surface-mount components to rapidly assemble your board. It automatically swaps between multiple vacuum tips and uses computer vision to make precisely and reliably assemble your board.

Specifications

| PNP Technology | Vacuum Pickup, Computer Vision, Automatic Tip Swap |

| Camera | 5 MP, Upward Facing |

| Tray: Types | Tape, Individual components |

| Tape Tray: Number of Slots x Tape Width | 6 x 8mm tapes, 2 x 12mm, 1 x 16mm Cut Tapes |

| Tray: Parts loaded | Max. 42 per batch |

| Min. Part Size | 0603 [1608 Metric] |

| Max. Part Size | 0.78” x 0.78” [20 x 20 mm] |

| Supported Formats | Centroid file (text file describing Reference Designator, Footprint, X/Y location, and Rotation). The file can be generated by your CAD tool |

Other specifications

Mechanical

General

| Max. Substrate Size | 6" x 6" [152 x 152 mm] [X/Y] |

| Max. Circuit Size | 4.9" x 4.8" [125 x 122 mm] [X/Y] |

| Heads: Weight | Less than 1.1 lbs [500g] per head |

| XYZ Positioning Repeatability | ± 0.8 mil [20 microns] |

| XYZ Positioning Resolution | 0.4 mil [10 microns] |

Without the Enclosure

| Frame: Size | 16.5" L x 14" W x 17.5" H [42 x 35.5 x 44.5 cm] |

| Additional Clearance Req. | 3" [7.5 cm] in front, 4" [10 cm] in the back |

| Frame: Weight | 30 lbs. [13.5 kg] |

| Shipping Box: Size | 21.5" L x 17" W x 27" H [55 x 43.2 x 68.6 cm] |

| Shipping Box: Total Weight | 50 lbs. [22.5 kg] |

With the Enclosure

| Enclosure: Size | 24.8” L x 17” W x 18” H [63 x 43 x 46 cm] |

| Additional Clearance Req. | 6” [15 cm] on the right |

| Enclosure: Weight | 46 lbs. [21 kg] |

| Unit: Total Weight | 81.5 lbs. [37 kg] |

| Shipping Box: Size | 30” L x 28” W x 22” H [76 x 71 x 56 cm] |

| Shipping Box: Total Weight | 106 lbs. [48 kg] |

Electrical

| Power | DC 24V 22A |

| Connection | Ethernet, Wi-Fi |

Software

| Installation | None (Software runs on-board) |

| System Requirements | Web browser (Platform-independent) |

| Recommended Browser | Firefox, Chrome |

| Offline Updates | Available on demand (USB3.0) |

Temperature

| Ambient: Operating | 50-100F [10-40℃] |

| Heat Bed: Operating | 75-300F [25-150℃] |

| Heat Bed: Max | 340F [170℃] |

Ambient Operating Requirements

| Ambient Temperature | 50-100F [10-40℃] |

| While operating without the enclosure | Protect the work area from air flows Avoid camera exposure to direct sunlight to improve the reliability of the Computer vision |

| Other | Operation in a ventilated area recommended |